If you work in a warehouse, you’ve likely seen your fair share of GHS labels. Whether you’re moving chemicals, pesticides, or some other hazardous materials, handling items safely is crucial.

One way to ensure safety and limit environmental hazards is through the use of GHS labeling.

GHS stands for the Globally Harmonized System of Classification and Labeling of Chemicals. The Globally Harmonized System (GHS) was developed by the United Nations to standardize the communication of hazardous chemicals.

GHS labels serve as an important communication tool in the workplace, as they aid in hazard classification. But what exactly is a GHS label?

What is GHS Labeling?

GHS labels are an essential part of occupational safety. These labels are used to inform workers and consumers about the potential hazards associated with a particular chemical, as well as information on properly handling hazardous chemicals.

They are designed to be easily understood, regardless of the language or country in which they are being used.

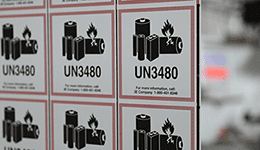

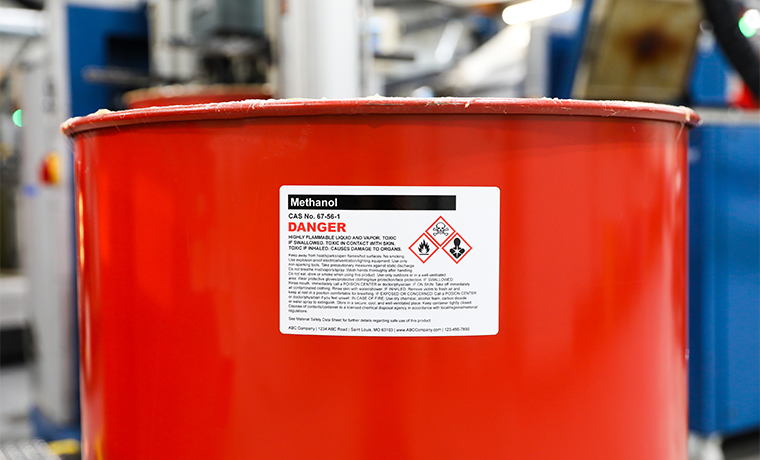

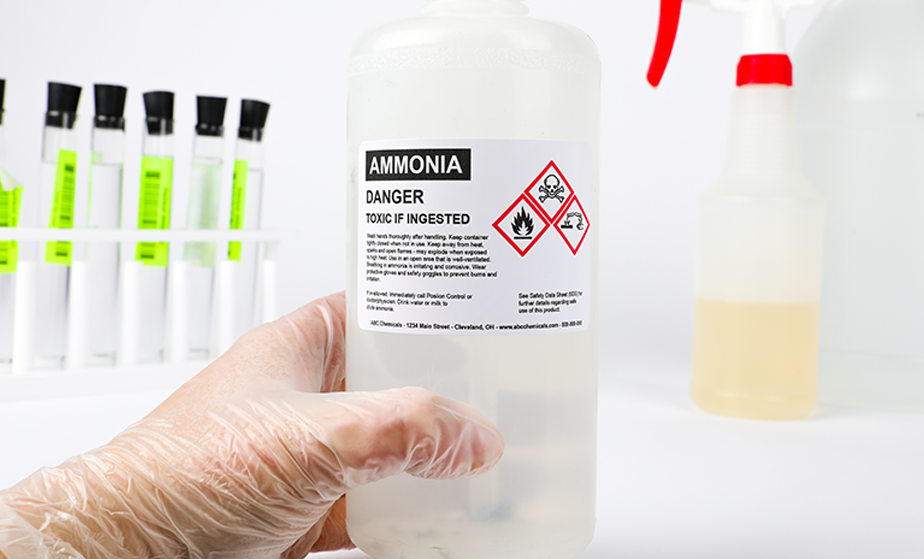

GHS labeling is a system that uses standardized pictograms, signal words, hazard statements and precautionary statements to convey important information about hazardous chemicals.

These labels also have to follow a specific format that include key elements such as:

- Product identifiers

- Supplier identification

- Hazard symbols

The purpose of GHS labeling is to ensure that anyone handling these chemicals, from the warehouse worker to the end consumer, can easily identify and understand potential hazards.

Primary vs Secondary GHS Labels

There are two types of GHS container labels:

- Primary

- Secondary

Primary GHS labels are used for containers that will be shipped, stored, or used in the workplace. These labels must contain 6 standard elements:

- Product names

- Hazard pictograms

- Signal words

- Hazard statements

- Precautionary statements

Secondary GHS labels, also called workplace labels, are used to provide additional hazard information for containers that are not intended for shipment, such as workplace storage areas or individual bottles used for dispensing. These labels must include the product name and appropriate hazard warnings.

What Kind of Products Require a GHS Label?

GHS labels are used for a variety of chemical products, including those used in industrial, commercial, and residential settings.

Any substance that is considered hazardous by OSHA or other regulatory agencies, such as the Environmental Protection Agency, must have a GHS label. These labels are required to comply with the Hazard Communication Standard.

Some common examples of products that require a GHS label include:

- Cleaning chemicals

- Pesticides paints and coatings

- Solvents, and laboratory reagents.

Additionally, any mixtures containing these hazardous substances must also have a GHS label.

It is essential to note that the responsibility for determining whether a product requires a GHS label falls on the manufacturer or importer of the chemical.

They must carefully evaluate the ingredients and hazards associated with their products to determine if a GHS label is necessary.

If there is ANY uncertainty, it is always best to err on the side of caution and include the required GHS label.

Why is GHS Labeling Important?

GHS labeling is crucial for several reasons.

It ensures that workers are aware of the hazards associated with the chemicals they are handling. This allows them to take necessary safety precautions to protect themselves and others around them.

GHS labels also help emergency responders quickly identify hazardous materials in case of accidents or spills.

For instance, consider an industrial facility where workers are routinely handling a variety of chemical substances.

Imagine that one day, a worker unknowingly mishandled a container of a particular chemical, leading to a spill. Without a GHS label, the worker and the emergency response team were unaware of the chemical’s highly corrosive property.

This lack of knowledge led to inappropriate handling during the cleanup process, causing several workers to suffer skin burns and inhale toxic fumes.

Had there been a GHS label on the container, workers would have known the dangers of the chemical and could have taken the necessary precautions, preventing injuries and health risks.

Another significant benefit of GHS labeling is that it promotes global harmonization and standardization of chemical labeling. This means that regardless of where a product is manufactured or used, the labels will contain the same information in a consistent format.

This makes it easier for workers to understand and follow safety protocols, even when dealing with chemicals from different countries.

In conclusion, GHS labeling is a critical aspect of chemical safety in the workplace. It ensures that workers have access to vital information about the chemicals they handle, promotes global standardization, and helps emergency responders react quickly in case of accidents. As such, it is essential for organizations to comply with GHS labeling requirements to ensure the safety and well-being of their employees and those around them.