If you’re regularly handling hazardous chemicals, you’re going to need to be stocked up on GHS labels. Short for Globally Harmonized System, GHS labels are critical tools for maintaining occupational safety. These labels provide essential information about the risks associated with a given chemical, helping to prevent accidents and ensuring those handling the substances are informed and protected.

GHS labeling is not only a matter of best practice but is also part of a global regulatory requirement for all chemical containers. It can seem a bit overwhelming to navigate these guidelines while running a business, but understanding the basics can make a world of difference.

That’s why we’re going to delve deeper into the specifics of GHS labeling requirements, so you can ensure that your workplace is compliant and ready to handle hazardous materials.

OSHA’s Hazard Communication Standard

The Occupational Safety and Health Administration (OSHA) is the primary regulatory body in the United States that oversees workplace safety. They have adopted the GHS standards as part of their Hazard Communication Standard (HCS) to ensure consistency in labeling hazardous chemicals.

Under this standard, employers are required to provide labels for all containers of hazardous chemicals in their workplaces. These labels must include specific elements and be in a consistent format to ensure clear communication of the potential hazards.

It is also important to note that OSHA requires GHS labeling on all containers of hazardous chemicals, regardless of size or quantity. This includes small containers used for samples or trial runs.

GHS Label Requirements

GHS labels require certain elements that help to quickly identify the potential hazards of a chemical and provide guidance on how to safely handle it.

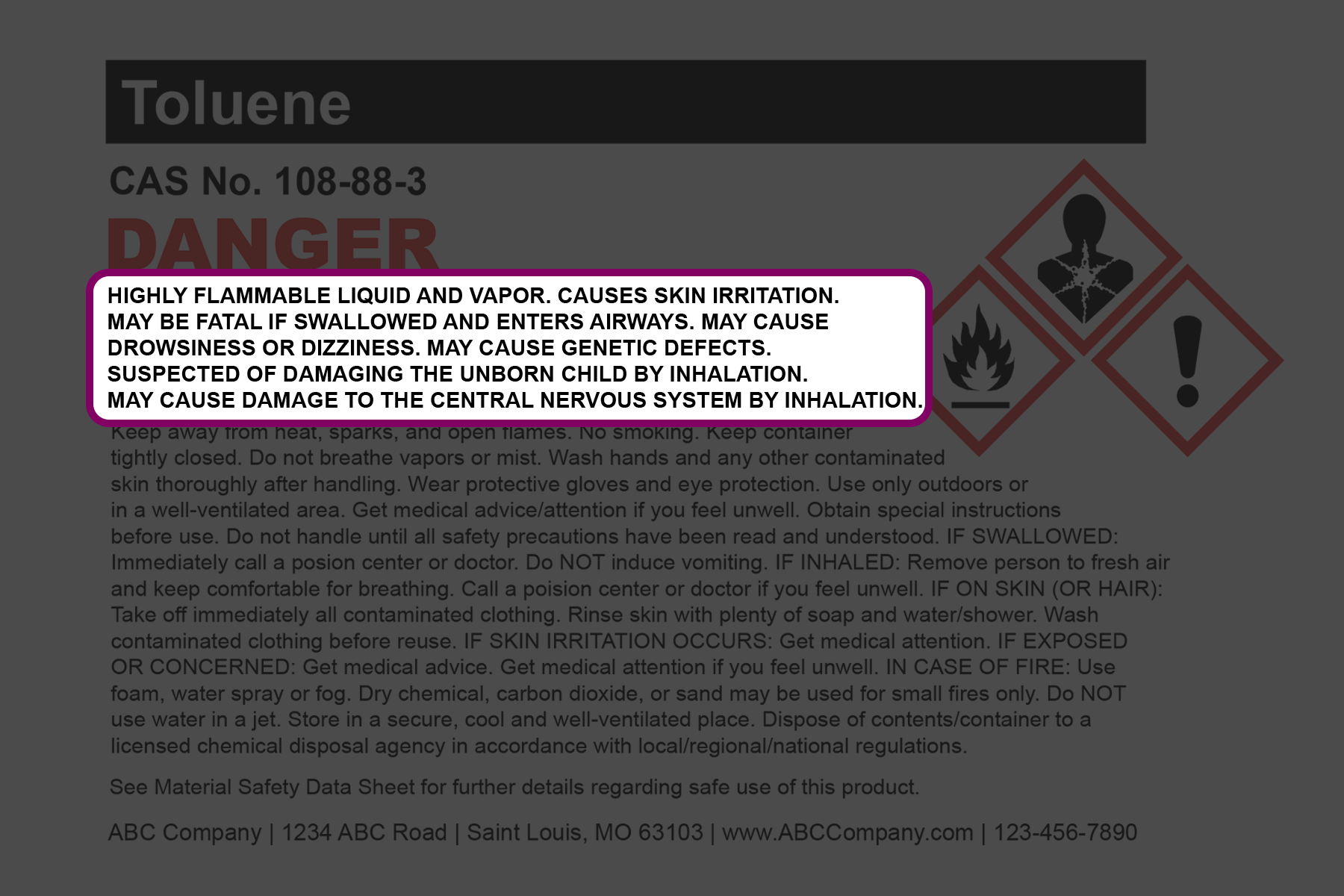

Six standardized elements must be included in a GHS-compliant label.

1. Product Identifier

A product identifier is the name or identification code for the hazardous chemical. This should match the identifier listed on the safety data sheet (SDS) for consistency. A safety data sheet is a detailed document that outlines the chemical’s properties, hazards, and safety precautions. Product identifiers can be chemical names, codes, or common names.

Along with the product identifier, you can include a batch or lot number to track specific batches of hazardous chemicals.

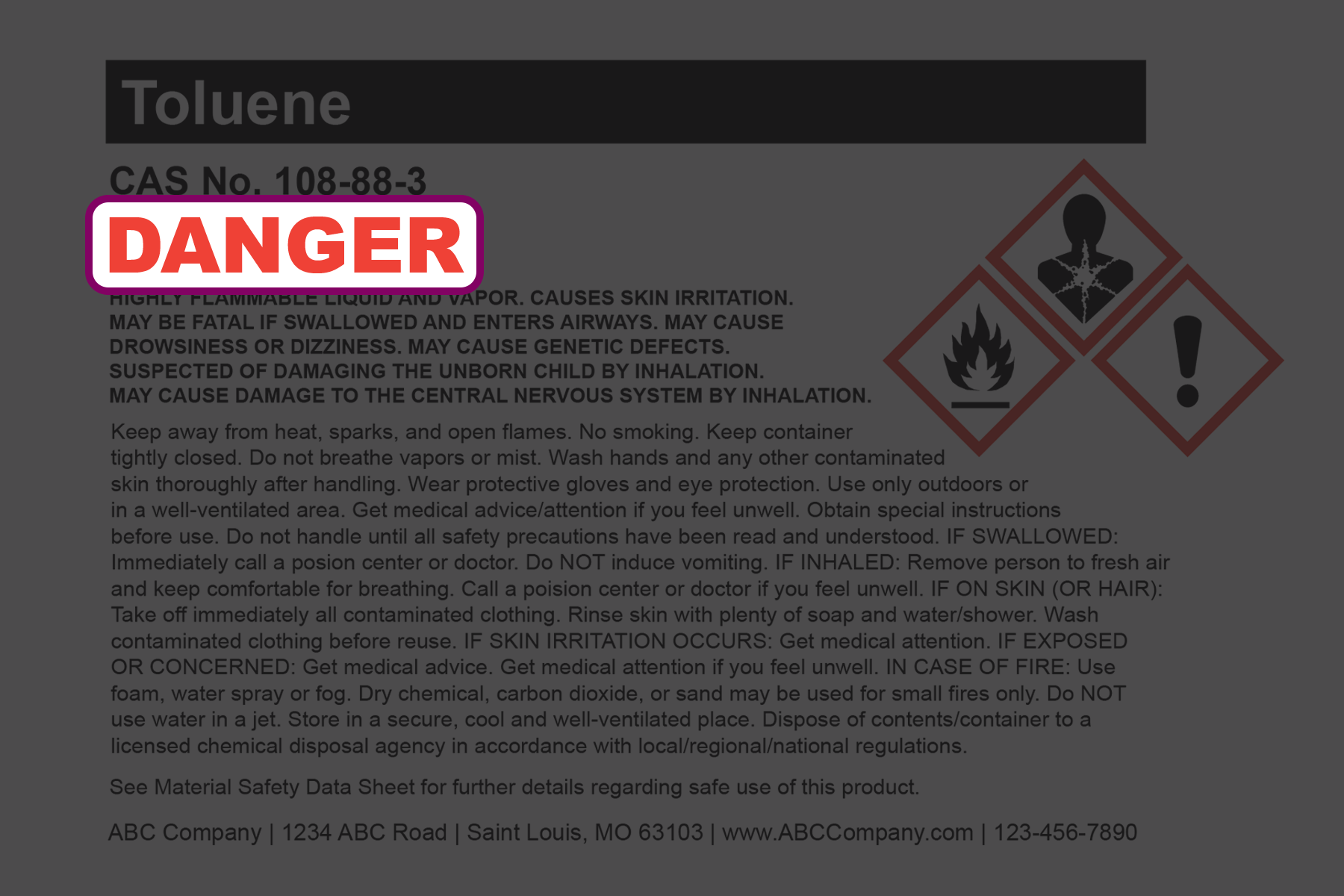

2. Signal Word

A signal word is a quick way to convey the severity of the hazard. The two options are:

- “Danger” for more severe hazards.

- “Warning” for less severe hazards.

The choice between “Danger” and “Warning” is based on a detailed hazard classification system. It begins with identifying the class and category of the hazard.

Hazard classes represent the nature of the hazardous effects, like:

- Flammable liquids or gasses

- Acute toxicity

- Carcinogenicity

- Skin corrosion

- Respiratory sensitization

Each hazard class is divided into categories, typically on a numeric scale, with ‘1’ representing the most severe hazards.

“Danger” is used for the most severe categories within a hazard class. For acute toxicity by oral intake, “Danger” is used for categories 1, 2, and 3, representing highly to moderately toxic substances.

On the other hand, “Warning” is used for less severe hazard categories. For example, for acute toxicity, “Warning” is used for category 4, which includes substances harmful if swallowed.

Determining the correct signal word is critical in GHS labeling. It provides an immediate indication of the hazard level to employees and ensures workplace safety.

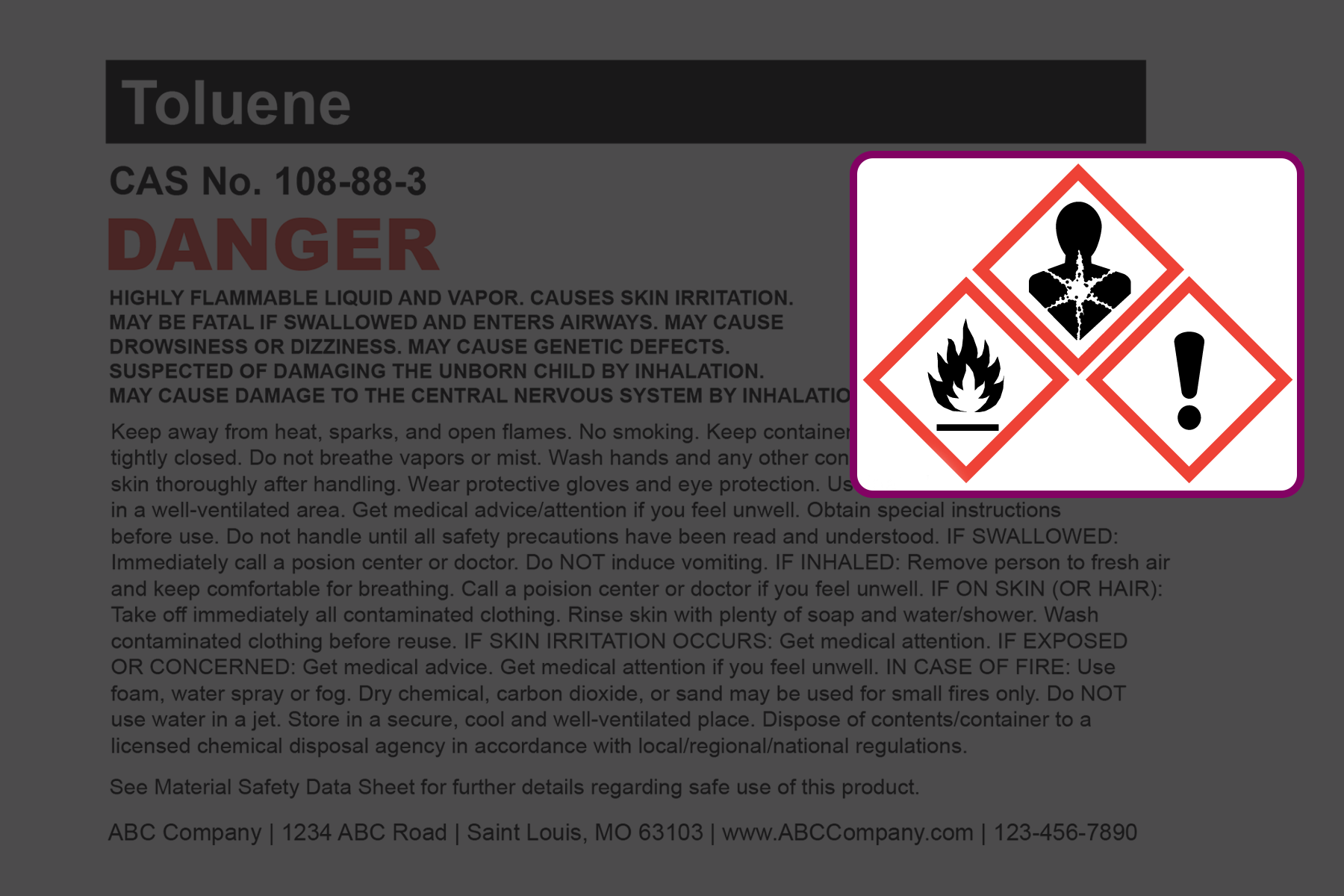

3. GHS Symbols (Hazard Pictograms)

Also known as hazard pictograms, GHS symbols are standardized hazard symbols that represent the type of hazard associated with the chemical. The GHS system has a total of nine symbols that are used to convey specific types of hazards, such as:

- Explosive

- Flammable

- Oxidizing

- Corrosive

- Acute toxicity

- Hazardous to the environment

- Health hazard

- Serious health hazard

- Gas under pressure

These symbols are easily recognizable and help to quickly convey the type of hazard present.

It is important to note that GHS pictograms are not interchangeable with other hazard communication systems such as NFPA or HMIS. Each system has its own set of symbols and classifications, so it is crucial to use the correct symbols for the GHS system.

4. Hazard Statements

A hazard statement includes hazard information; it describes the nature and degree of the hazards posed by a chemical. These statements are assigned to each hazard class and category under the GHS system and help to further clarify the potential hazards associated with a chemical.

Hazard statements may also include additional information such as precautionary measures to take when handling the chemical, first aid instructions in case of exposure, and any specific hazards associated with the substance. It is important to carefully read and understand hazard statements to ensure safe handling of chemicals.

Choosing the correct hazard statement is determined by the classification of the chemical in question. The GHS system classifies chemicals into specific hazard classes and categories based on their physical, health, and environmental hazards. There are different classes and categories, each with their own hazard statements.

Let’s take a look at the process of choosing the correct hazard statement.

Step 1

Identify the hazard class of your chemical. For example, if your chemical is a flammable liquid, it falls under Class 3: Flammable Liquids.

Step 2

Then, you must determine the category within that class. Continuing with our example, if your chemical has a flash point below 60°C and an initial boiling point above 35°C, it falls under Category 2 and would have the hazard statement “Highly flammable liquid and vapor.”

Step 3

Once you have identified the correct hazard class and category, you can choose the corresponding hazard statement from the GHS system. This will provide a concise and standardized description of the potential hazards associated with your chemical.

In essence, the chosen hazard statement is directly linked to the assigned classification of the chemical. One can find these classifications and associated hazard statements in the chemical’s Safety Data Sheet (SDS), which is provided by the chemical’s manufacturer or supplier. If you’d like to see an extensive list of hazard statements, click here!

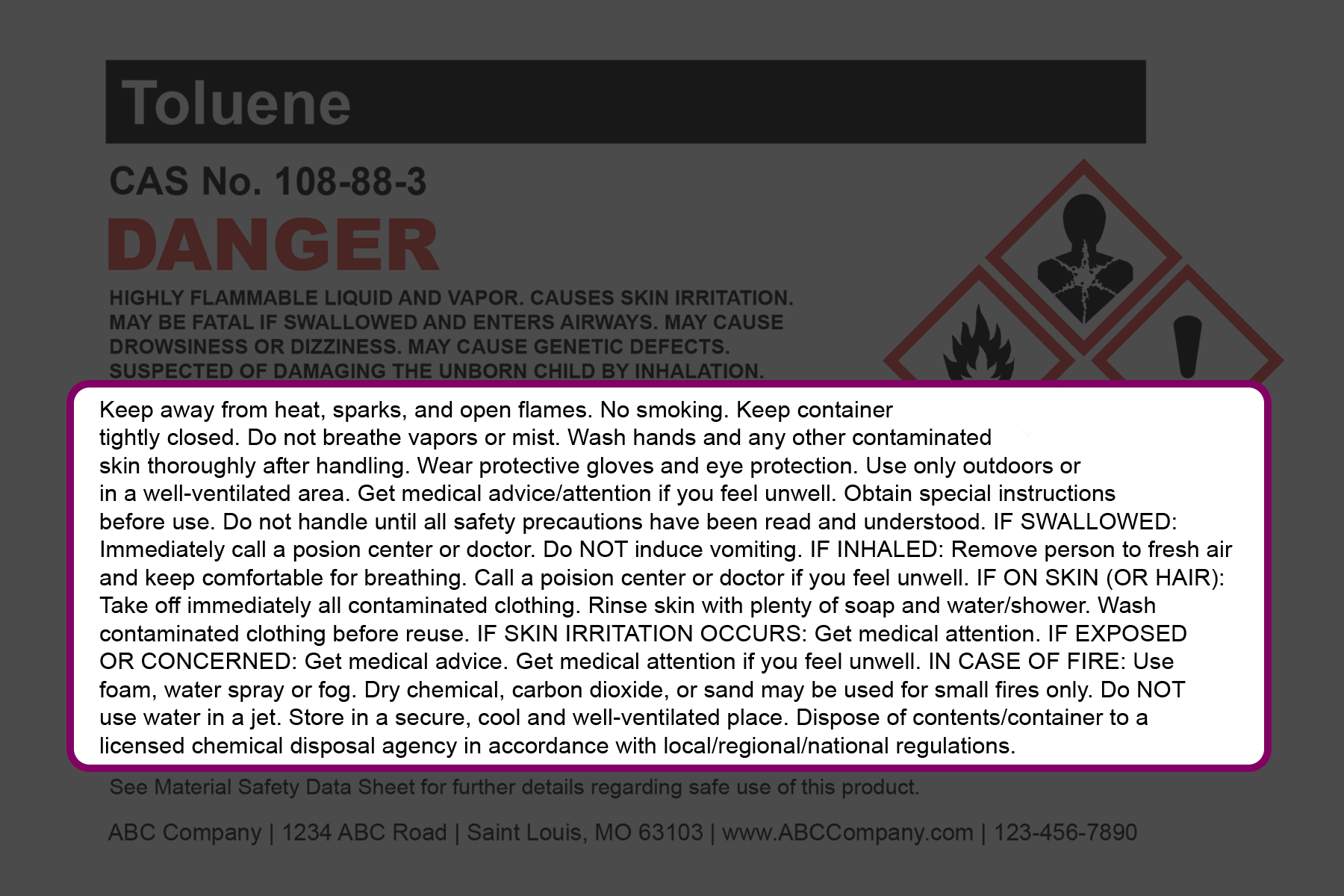

5. Precautionary Statements

A precautionary statement guides how to handle and store hazardous chemicals safely. These statements are also assigned to each hazard class and category under the GHS system and provide specific instructions on how to prevent or minimize exposure to a hazardous chemical.

Precautionary statements typically appear on labels and SDS in conjunction with the relevant pictogram and hazard statement. For example, a label for a highly flammable chemical may include precautionary statements such as “Keep away from heat/sparks/open flames” or “Store in a well-ventilated place.”

It is important to read and understand all precautionary statements before handling any hazardous chemicals. Failure to follow these instructions could result in serious safety hazards.

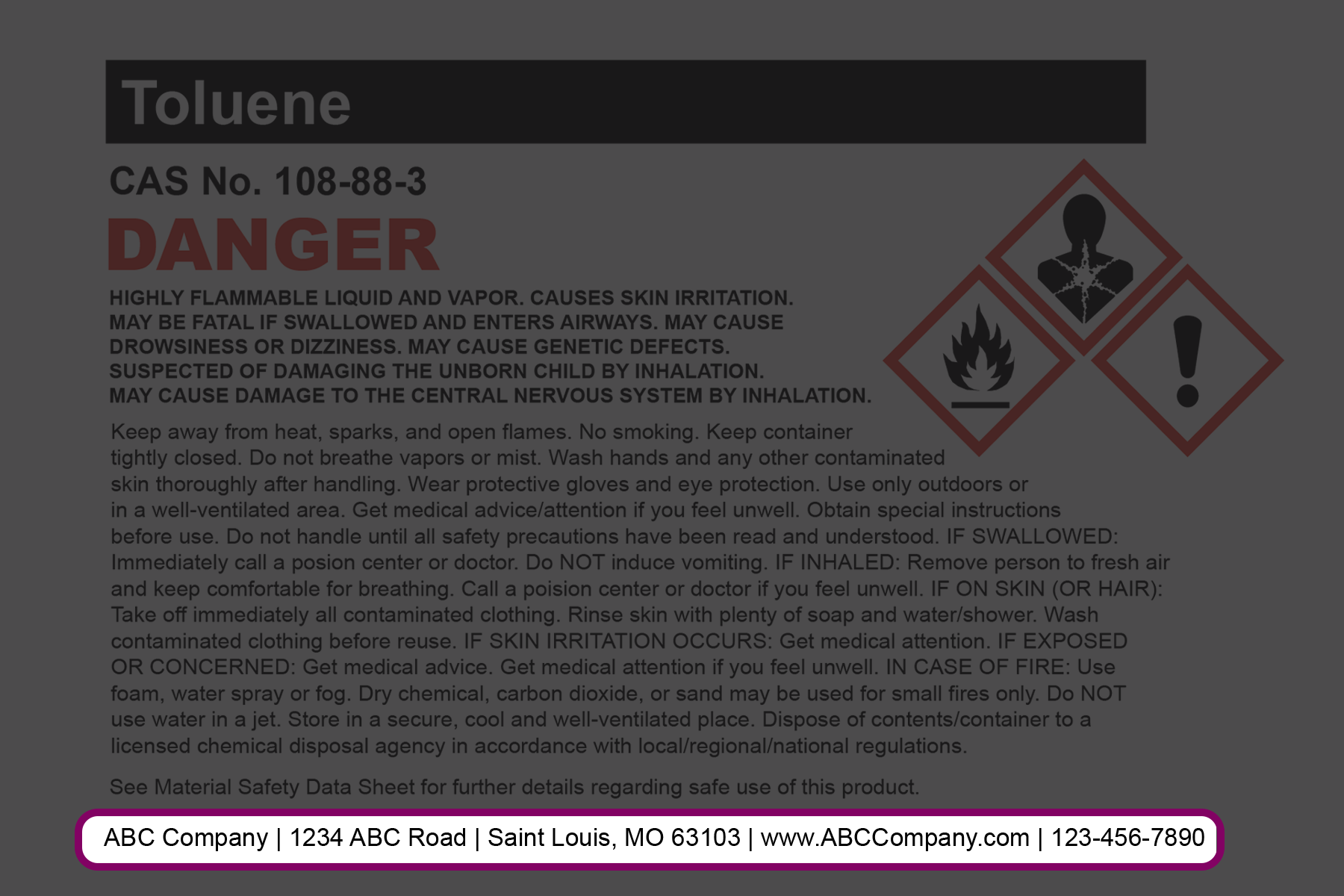

6. Manufacturer Information

Manufacturer information includes the name, address, and telephone number of the chemical manufacturers, importers, or other responsible parties. This information is required by law to be included on both labels and SDS. In the event of an emergency, this information can help individuals quickly and easily contact the appropriate party for assistance.

In addition to contact information, manufacturers may also include information such as product identifier, batch or lot number, and date of production or expiration on labels and SDS. This information can assist in identifying and tracking specific products, especially in the case of a recall.

It is important to note that manufacturer information may change over time, so it is crucial to always check for the most up-to-date information on labels and SDS.

Additional Elements

In addition to the six required elements, some optional elements can be included on a GHS label. These include:

- Supplemental Information: This can include additional information about the chemical such as specific hazards or safety precautions.

- Harmonized System (HS) Codes: These codes are used for international trade and help classify chemicals into specific categories.

- QR Codes: These codes can be scanned with a smartphone to access additional information about the chemical, such as safety data sheets (SDS).

Additionally, the information on the label must be accurate and up-to-date, as hazards and safety precautions can change over time.

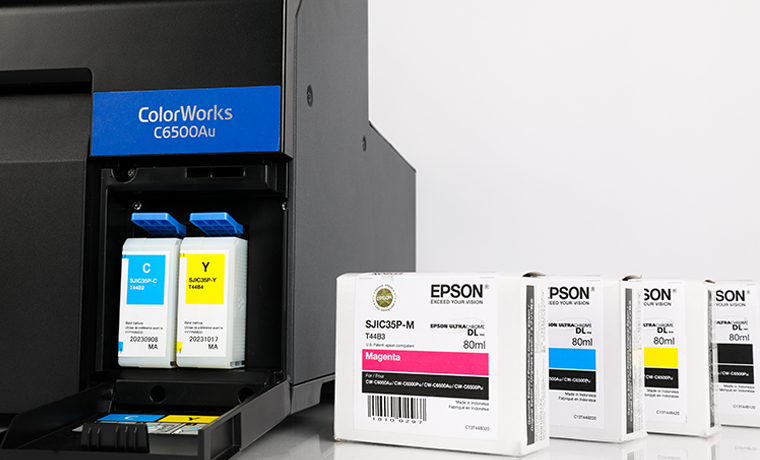

GHS Label Materials

When it comes to GHS labels, the choice of material and adhesive is just as important as the message it relays. GHS Labels should ideally be made from materials that are BS5609 certified.

BS5609 is a certification that guarantees the durability of printed labels and their adhesives, specifically for marine environments. This certification is a globally recognized standard that guarantees the label can endure:

- Harsh weather conditions

- Extended exposure to water

- UV sunlight

If you are looking to print GHS labels in-house, they will require ink that meets BS5609 certification for durability. Epson ColorWorks Pigment Ink is a notable example that complies with this standard. This certified ink can withstand harsh marine conditions, preserving safety information legibility. A great printer to go with this ink is the Epson C6500A, perfect for printing GHS labels.

As chemicals often need to be transported across seas, having a BS5609 certified label ensures crucial safety information remains legible and intact throughout the journey, reducing the risk of accidents due to misinformation or lack of information. Hence, selecting materials with this certification when creating GHS labels is a proactive step towards safety and compliance in the global supply chain.

Keep Your Warehouse Compliant

GHS labels play a vital role in promoting workplace safety and ensuring compliance with regulations. By implementing proper labeling procedures, you can ensure that your warehouse or facility remains compliant with GHS standards. Additionally, regularly monitoring and updating labels to reflect any changes in chemical products can help prevent potential hazards and accidents.

It is also essential to properly train employees on how to read and interpret GHS labels to ensure that they understand the hazards associated with each chemical. Regular safety audits can also help identify any potential issues and ensure that all GHS labels are up-to-date and correctly displayed.

By consistently following GHS labeling regulations, not only are you promoting a safer work environment, but you are also avoiding penalties or fines for non-compliance. Keeping your warehouse compliant with GHS standards will have you on the right track to maintaining a safe and efficient workplace.